Any traditional centrifugal pump or positive displacement pump when transferring fluids with high pressure, low flow, and low viscosity while handling entrained vapors or fluids near their boiling point. These conditions generally hinder the performance and reliability of most pumps, causing cavitation and pulsation. However, there is a solution to this problem thanks to the regenerative turbine pumps. In this Application Bulletin, we will discuss what a turbine pump is, how it operates, and the benefits of using a turbine pump.

What is a Regenerative Turbine Pump?

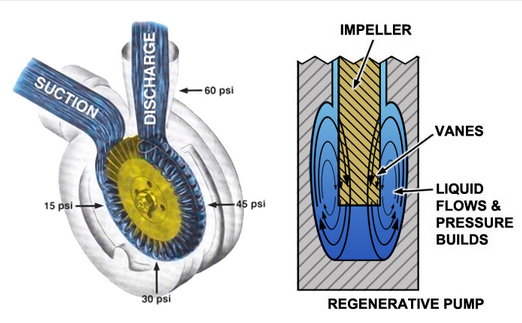

It is a rotodynamic pump that combines the high discharge of a positive displacement pump and the flexibility of a centrifugal pump. While operating at the fluid condition with high pressure, flow, and low viscosity, that can maintain efficiency, keeping the pump from being damaged. They are used in many applications like boiler feed and high-temperature water and oil heat transfer.

How It Works

As shown in the image on the right, they operate with an impeller that is a rotating, non-contacting, freewheeling disc that has many small cells on its periphery. When the liquid enters the suction port of the pump it is picked up by the impeller and instantly accelerated around in the narrow hydraulic channel, surrounding the cells. The winding of the liquid many times within one revolution incrementally builds pressure. The spiraling of the numerous small liquid cells creates the differential pressure capability of the pump.

Benefits

- Generates high head and high discharge pressure

- Reduces the impact of cavitation and pulsation

- Better at handling gas-liquid mixtures

- Compact Design

Conclusion

If you are interested in a turbine pump for your application, please contact our experts and see what we can do for you!