Water and sewer sources are usually held by municipalities with billing for both fresh water and discharge to sewer. The sewer charge is normally a similar or exact billing on the assumption that the water once used is returned to the sewer for treatment before release into streams. With no measurement of the actual effluent, this can be a substantial and unnecessary financial outlay. To counter this, a common practice is to measure the effluent discharge flow, the difference between input to the facility and discharge to sewer reflecting the actual consumption by the process, thereby reducing the sewer billing by that amount. A great system to employ this process is a magnetic flow meter system. In this Application Bulletin, we will discuss magnetic flowmeters operating principles, how this system is applied, and how the system works.

Magnetic Flowmeters Operating Principle

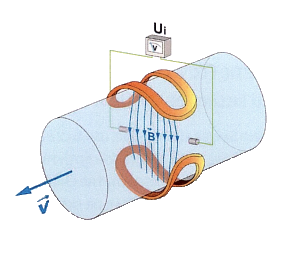

Magnetic Flowmeters usually referred to as “Mag Meters” operate on this principle of induced voltage recognized by Faraday’s Law. This law states that when a conductor passes through a magnetic field, a voltage is generated which is a direct indicator of the velocity of the conductor. In this case, the conductor is the wastewater sent to the sewer. This voltage is used to calculate the volume of flow based on velocity and area. The flow information is expressed as a local display of rate and total, analog and pulsed outputs for display, totalization, and data collection.

How it Works

The magnetic flowmeter is an accurate and repeatable flow sensor and is ideally suited to the task of effluent measurement. Due to the design of the flowmeter, an unobstructed tube is usually fitted to the same pipe size, forming a part of the piping system with no restriction. The meter has no moving parts, this is important because no restriction in the line, therefore no pressure drop. The design also allows the unimpeded flow of suspended waste to the sewer. The typical accuracy of the meter when properly applied is 0.25% of the actual flow.

The design of the magnetic flowmeter employs Faraday’s Law. This states that voltage can be generated by passing a conductor through a magnetic field, the voltage generated being directly proportional and linear to the velocity of the conductor. In this instance, the conductor is the conductive liquid. Once this voltage is generated it is converted to a signal in the electronics package from which the rate of flow and total flow can be deduced, displayed, and transmitted as a volumetric flow for both rate and totalization purposes.

Once the volumetric flow is determined, this amount can be used to compare to the incoming fresh water, the difference between the two figures being the amount consumed as opposed to being returned to the system for waste treatment. These substantial savings can be added to the user’s profit margin as opposed to being collected as resource billing as a sewer charge. Simply put, the meter saves sewer charges by recording and documenting the actual use of water. This simple step guarantees substantial savings and pays for itself very quickly.

Installation of Magnetic Meters

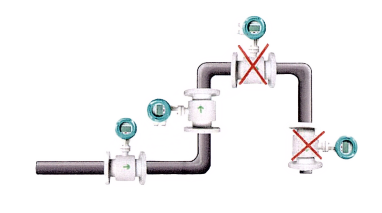

Magnetic meters must be full of liquid to operate as designed. As shown in the image to the right, the meter should be placed in a low place in the piping or a vertical position with the flow going upwards. either of the installs will ensure a full pipe. It’s necessary when mounting the meter in a horizontal position to keep the electrodes in a horizontal plane to avoid entrapped air from crossing the electrodes and rendering erratic readings.

Conclusion

We hope that you have an understanding of how magnetic meters work, how they operate in effluent measurement and billing, and how they are installed. You should now know to make an informed decision for you and our operation. If you are interested in these systems like this, contact our experts today and see what they can do for you!