Introduction

Maintaining a plant or system can be a challenging endeavor, demanding careful choices to ensure efficient and successful operations. To assist in making well-informed decisions, we are excited to introduce our new series, “Application Bulletins.” Through these bulletins, we delve deep into various industry applications and explore the equipment best suited for them. In this edition, we shed light on automatic batching systems. We will explain what these systems are, how they function, and explore the different types available. We hope is blog will give you a clear understanding of automatic batching systems and equip you with the knowledge to make informed decisions to help your business.

What is an Automatic Batch System?

In simple terms, the system is designed to allow a preset input for a specific amount of product to be dispensed as a volume or mass measurement with automatic measurement and a final control element monitored and controlled by the dispensing controller. We understand the challenge of choosing the right automatic batch control solution for your system. Whether you opt for mechanical or electronic options, the functions are essentially the same, both systems presenting advantages dependent on the operation and the operator. Whether a mechanical or electronic batch system, the components are composed of three components, these being a sensor, a controller, and an actuated control valve.

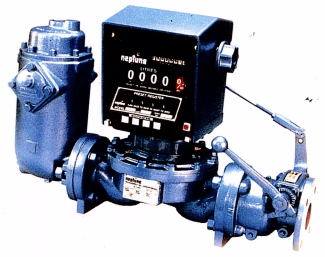

Mechanical Systems

As the name implies, a mechanical system does not require any power source but rather uses a mechanical sensor, controller, and a valve which is mechanically actuated and manually reset when a batch run is completed. There are numerous advantages to a mechanical system, like usage in hazardous locations due to no power requirements and a quick learning curve for the operator. If a mechanical system doesn’t fit the needs of your application, another great option is an electronic batch control system

Electronic Batch Systems

An electronic system operates much the same as a mechanical system, but all components are electrically powered with enhanced display features. This allows a much greater selection of sensors such as magnetic flowmeters, Coriolis (mass) meters, positive displacement meters, etc. These meters normally transmit a scaled pulse signal to the electronic controller, and can completely automate the operation of the actuated valve, closing and opening as required. Electronic systems are generally much more resistant to mechanical failure due to the sensor having no moving parts, as a result, electronic systems are more accurate and have better repeatability.

The UniBatch Solution

The UniBatch is a proprietary fully integrated bath control system that is available in sizes ½”- 2′ in either bronze or stainless steel. The system comes pre-wired and configured for either gallons or pounds with a very simple and operator-friendly controller which is matched with a high-accuracy Burkert paddle wheel sensor and a fully controlled actuated valve. The system is very cost-effective and simple to install and operate and is optimal for any flowable liquid with chemical compatibility with wetted surfaces.

Conclusion

We hope that this gave you a proper understanding of automatic batch control systems, what they are, the different types, and how they all function. If this seems like a solution needed for your operation, please contact one of our experts to help you find your ideal solution! We hope to see you again!