When it comes to handling a conductive liquid such as asphalt sealer, you require a system that offers both reliability and accuracy in its dispensing or measuring capabilities. While a mechanical meter could be utilized for this specific purpose, it is strongly advised to opt for a magnetic flowmeter system. This system presents several advantages over its mechanical counterpart. In this Application Bulletin, we will delve into the functioning of the magnetic flowmeter system, highlight its benefits, and examine the components that constitute this system

How It Works

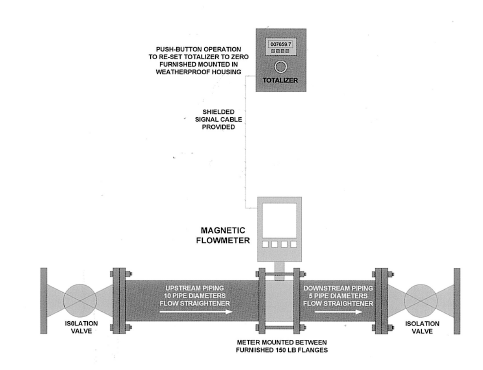

The system as pictured on the the right show a magnetic flowmeter properly installed and connected to a flow totalizer, which is designed to receive a signal from the meter, accumulate total flow, and execute simple re-set to allow the dispensing operation to occur easily without error. All parts shown are furnished as a package from us, to include all peripheral wiring (50′) along with flanges, bolts, spool pieces, isolation ball valves, and required electronic components. This system also requires little expertise for installation and operation. It can also be powered by AC or DC and is furnished as a weatherproof systems.

Advantages of The System

- No moving parts

- No obstructions in the meter

- High accuracy and repeatability, typically >.25% of the actual volumetric flow rate

- Permanent totals and resettable totals are standard in the meter

- Accuracy is measured on actual volumetric flow, i.e. whatever the flow rate, the accuracy will be the same

- The system is repeatable, it will measure and report the same each time

- Rate of flow display is standard on the meter

- Easily replaceable components

Components of The System

- Size 2″ Krohne Model Optiflux 1000 Magnetic Flowmeter with compact-mount Model IFC100 Signal Converter

- Stainless Steel Ground Rings

- KEP Minitrol Electronic Resettable Totalizer

- Weather-Proof Totalizer Housing

- 20″ Upstream Flanged Spoolpiece

- 10″ Downstream Flanged Spoolpiece

- 2 Each Flanged Stainless Steel Full-Port Isolation Ball Valves

- 50′ Shielded Cable

- All required mounting hardware for the meter

- Pre-Configuration of meter and totalizer

- Required electronic components for terminations

- Required gaskets

- Detailed install instructions

- Manufacturers’ Instruction Books

- Shipped assembled

Conclusion

If you are interested in this system or any of our other product, contact our experts today and see what they can do for you! We hope this helps you have a clear understanding of the application and help make you make an informed decision for your operation.